The TOX®-TWINpoint sheet metal joining system is an alternative technology in relation to inseparable methods like welding and riveting. In many cases, it also replaces bending and screwing methods.

TWINpoint Joining System

The double point with almost double strength

The TOX®-TWINpoint sheet metal joining system is an alternative technology in relation to inseparable methods like welding and riveting. In many cases, it also replaces bending and screwing methods.

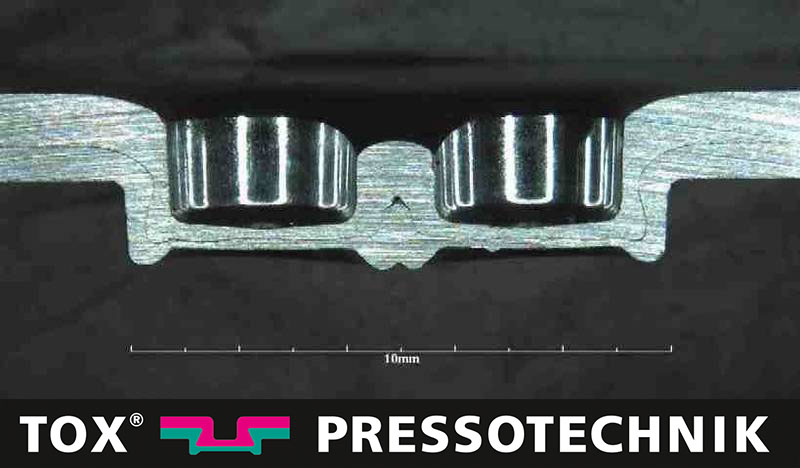

The TOX®-TWINpoint along with the TOX®-Round-Point initial joint and its variants, form a wide range of possibilities to join sheet metal. This new joint is a 2 in 1 solution – two joints formed from one stroke of the press, using one set of tools (punch and die). The basic aim was to improve productivity and protect joints against rotation The exact characteristics of the new joint are presented below.

Research into the limits of the round joint has resulted in the latest, TOX®-TWINpoint technology. The double-joint design, made with a single tool strike, enables small parts or narrow flanges to be joined. Compared to the basic TOX®-Round-Point joint, the single-element die of the double joint opens up new possibilities for the clinching of small parts

The key attribute of the new joint is its shear strength, which is up to double, and its tensile strength up to 1.5 times greater than in the single TOX®-Round-Point. The very close positioning of the two tool cavities reduces the zipper effect which might occur on long components where joints are arranged in a row (peeling load charge on the end position might cause end points to tear open, which is reminiscent of a zip fastener).

The joint by definition protects sheets from rotating. Single TOX®-Round-Point joints have equal load carrying capacity on all sides - the positioning of the tools is irrelevant.

So how does it look in the case of the double TOX®-TWINpoint joint, where the clinching points are adjacent and the strength values may be even double? It turns out that the effect of the form direction on the joint's strength (along both joints or crosswise), is not even noticeable. Especially in the case of soft materials, the increase in strength compared to a single joint is highly distinct. Such characteristics as the increase in production output (two joints in the time taken for one), anti-rotation prevention, the joint's greater strength irrespective of the force direction, and the reduction of the zipper effect are the main advantages of the TOX®-TWINpoint technology. The key to this solution is the very close proximity of two standard round joints. This means that the distance between the points is equal to their diameter, with no loss of properties.

In hundreds of tests conducted, the TOX®-TWINpoint always proves its high quality and strength. The scope of its applications ranges from clinching thin 0.2 mm steel, aluminium, copper or special sheets and other components with a combined thickness of 10 mm. TOX®-TWINpoint can be used for any point diameter of joint, from 1.2 mm all the way up to 12 mm, every time achieving optimum resistance. Using the TOX®-TWINpoint joint allows you to achieve an efficient, repeatable and safe system for clinching sheets with a quality guaranteed by the well proven and tested TOX®-Round-Point.

Quality control of the joint requires only the non-destructive method of measuring the remaining bottom thickness after the clinching process, the so-called “control dimension X". The simple measurement by commercially available instruments reduces the costs and risks associated with the manufacture of faulty products. These features mentioned make the TOX®-TWINpoint one of the most interesting innovations in the field of sheet joining, one which introduces a new quality to current clinching processes. None of the companies offering competing press-joining techniques have a joint with the features offered by the TOX®-TWINpoint.

|

Contact

GB: +44 1785 904667

Contact form

|

|

Cookie Information

We use cookies to give you the best possible experience when using our website. You can block or regulate the use of cookies by adjusting your browser settings accordingly. |