The progressive automation of production and assembly equipment poses great challenges for the manufacturers of manual workstations as well as of partially or fully automatic workstations and machines, particularly with regard to safety. The terms CE- und EC-compliance might be widely talked about. However, it can frequently be observed that many devices might display a CE label, but the specifications based on the standardisation according to DIN EN ISO 13849-1 or DIN EN ISO 12100:2011-03 are not met. The standardisations with regard to electrical construction and equipment or mechanical construction and design are to support designers and mechanical engineers to produce safe machines and circulate these with the CE certificate.

Products and systems from TOX® PRESSOTECHNIK GmbH & Co.KG are always produced and equipped according to highest quality specifications and safety standards. This applies particularly to press systems and manual or partially to fully automatic workstations, which are equipped with electro-mechanical drives TOX®-ElectricDrive for generating the stroke and the press force. The example of a TOX®-Press System CMB of type ecoLine shows how standard components (TOX®-Universal Base Frame UUM 1-350 including 3-sided protection of macrolon, TOX®-C-Frame-Bench Press CMB 004, TOX®-ElectricDrive EQ-K 025 drive with safety brake, TOX®-2-hand safety control STE-1-503 with safety module for performance level “e”) are used to create complete, operationally safe manual workstations with EC declaration of conformity.

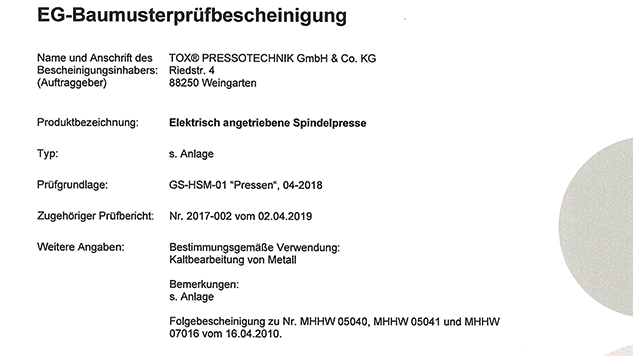

Servo-electrical presses are to be categorised under the Machinery Directive “for the marketing of machines and incomplete machines”, Annex IV machines “Not fully developed according to harmonised standards which cover all GSA (health and safety requirements)”. The EC-type examination for the TOX®-ecoLine CMB 004.025 was carried out by BGHM (Wood and Metal Trade Association). For each variation of the tested machine, another type examination would have been required. To simplify this, the documentation as well as the health and safety requirements were checked and measured on the assembled standard machine. Furthermore, the QSS (quality management system) for the production process “Orders with servo-electrical presses” was also subjected to comprehensive tests and final auditing by BGHM (checking the process for the design and production of customer-specific presses, based on ISO 9001 as well as type examination for TOX®-ecoLine CMB 004.025). Here, only qualified designers may design TOX®-ElectricDrive-Presses, and only approved material may be used for the standard and special presses. TOX® PRESSOTECHNIK passed process testing and auditing with distinction and is thus one of the first press manufacturers to be allowed to assess EC compliance of the said manual workstations with electro-mechanical servo drives independently and issue respective certificates! This ensures customers receive a safe manual workstation.