The great importance mechanical joining processes have as an alternative or frequently also as a complement to the thermal joining processes despite progressive use of laser technology is underlined by the following figures: Several thousand rivet connections can be found already today in a lightweight car on the body as well as on components. In a production line with approx. 1000 vehicles per day, this means about 2 million rivets must be set quality- and process-reliably. Consequently, technological joining know-how is required on the one hand, and on the other, production-related competence.

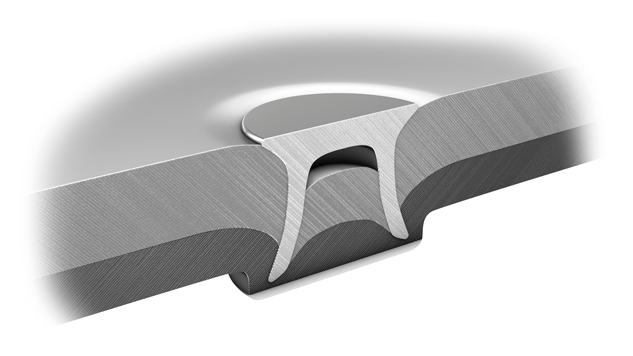

Safe rivet connections, high system availability, adaptability into systems, process robustness and intelligent error prevention, taking of responsibility – these are the central demands of the automotive manufacturers and their suppliers which make TOX® PRESSOTECHNIK a partner in demand! Based on the patented sheet metal joining technology TOX®-Clinching, which is recognized worldwide, well-founded know-how for joining several sheet metals especially by “riveting without rivets” is available to customers. The joining of sheet metals by “riveting without own rivet” is based on this, in other words: TOX®-Joining Systems are designed in “open architecture” for the process-reliable processing of very different rivet types, and can apply semi-hollow punch rivets, solid punch rivets, ClinchRivets® as well as functional elements of all manufacturers.

The consistent design for high system availability is owed to the fact and not least the industrial experience that rivets that move during transport as loose bulk material as well as during separation and conveyancing within the riveting system cause particulate wear debris, which can result in faults in the system. For this reason, TOX®-Riveting Systems do not let the wear debris get into the system in the first place, or the special design of conveyor technology during “internal” transport causes as little further wear debris as possible. An example here would be the separately acting system components of rivet bin, rivet conveyor for 2 rivet types, 3D printed rivet separators with integrated output priority, rivet shot units, rivet switches, rivet tail sections (all equipped with dust collection chambers) as well as a cyclone separator for cleaning the conveying air. The entire system is designed to the last detail and down to the setting tool by means of FEM (Finite Element Method) and FMEA (Failure Mode and Effect Analysis), whereby aspects like forces occurring inside and out, ideal force transmissions, required accuracies and finally a minimal total weight of the actual setting system (robot tong, drive, tool holding fixtures) were taken into account.

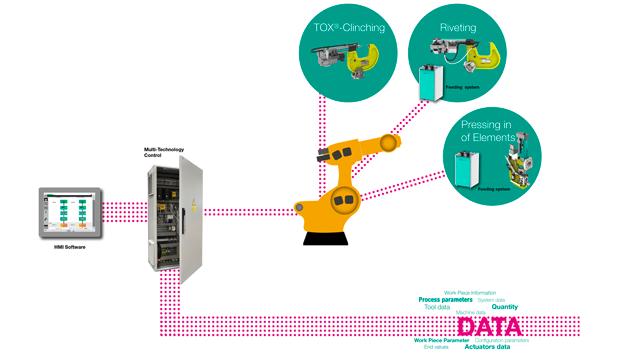

Process robustness and intelligent error prevention are ensured on the one hand by monitoring die breakage by means of dynamic pressure measurement instead of optical systems, and on the other hand by support through ML (Machine Learning) for independent correction of air pressure fluctuations on factory side and states of use (contamination, oil, wear) including additional functions that can be integrated like permanent system leak tests for immediate detection of any insufficient maintenance. The “integrated tolerance” with regard to electromagnetic interference fields also contributes to the robustness of the riveting processes. The riveting systems remain functional if 85 kA aluminium welding tongs in the outer field do not work closer than 1,000 mm and 20 kA steel welding tongs not closer than 600 mm. Furthermore, the systems are resistant against geometric dispersions as well as coating pits of the rivet. What’s more, the ML-supported detection of the rivet signature enables programmed sorting of the desired rivet type without mechanical interference, ensuring high flexibility and resulting in low retooling times. In this context, the possibility of the feeding of rivets “from behind” as well as the automatic die change are to be mentioned. Even the joining tongs on the robot and the associated control are system compatible and thus easy to replace, which not only results in a change of technology which is flexible according to requirements, but also brings organizational advantages with regard to the spares inventory, training and documentation

The intelligent error prevention also aims for only “true” errors leading to a production stop. This is possible through separation of true errors and acceptable process variants, as well as through implementation of expert knowledge into process monitoring. Furthermore, up to 80 sensors/counters are integrated per TOX®-Joining System, to monitor all operating states and be able to make corrections immediately when required. The most important part systems communicate here via EtherCAT component with the multi-technology control as EtherCAT master with multi-technology TOX®-Software HMI 3.0. The TOX®-Joining Systems are completed here by the aforementioned taking of responsibility – in the shape of documented optimization and validation of all joining tasks and parameters with the TOX®-Test Report as well as an unlimited warranty!